"ttyymmnn" (ttyymmnn)

"ttyymmnn" (ttyymmnn)

10/31/2013 at 10:05 • Filed to: Planelopnik

2

2

11

11

"ttyymmnn" (ttyymmnn)

"ttyymmnn" (ttyymmnn)

10/31/2013 at 10:05 • Filed to: Planelopnik |  2 2

|  11 11 |

You may recall the dramatic video of a China Airlines B737-800 catching fire at Okinawa's Naha Airport back in 2007. It took emergency crews over four minutes to reach the burning plane, and the aircraft was completely destroyed. Fortunately, there were no fatalities, and only a few passengers sustained minor injuries in the evacuation. A subsequent investigation determined that the fire was caused by a fuel leak due to the omission of a single washer after maintenance on the No. 5 leading edge slat assembly. The FAA !!!error: Indecipherable SUB-paragraph formatting!!! to illustrate what happened in that slat assembly, and how the fuel tank was punctured.

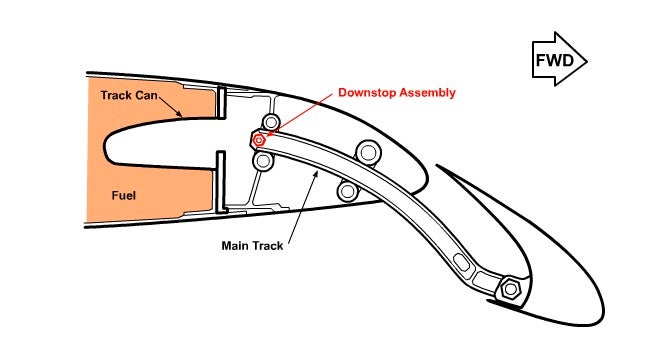

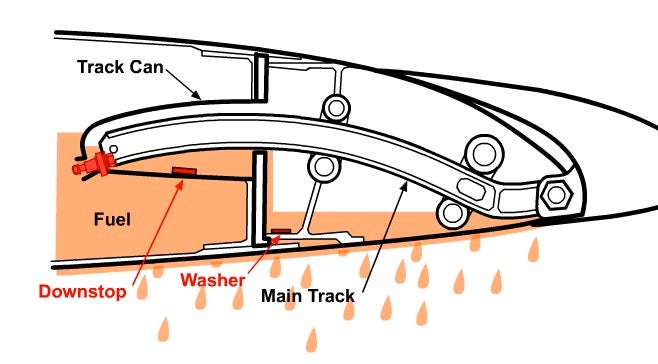

This still from the video shows how the leading edge slats are extended by the Main Track, and that extension is halted by the Downstop Assembly. When retracted, the Main Track is housed in the Track Can, which is integrated into the wing fuel tank and only large enough to house the Track.

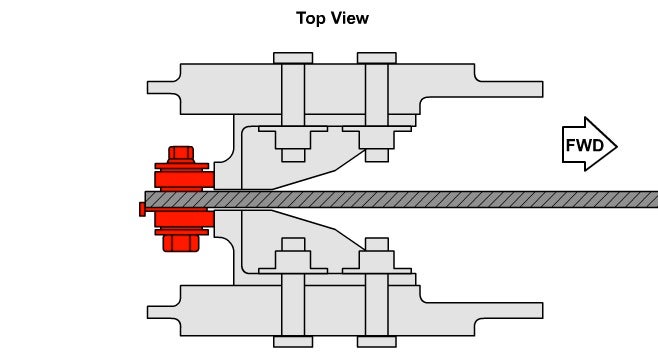

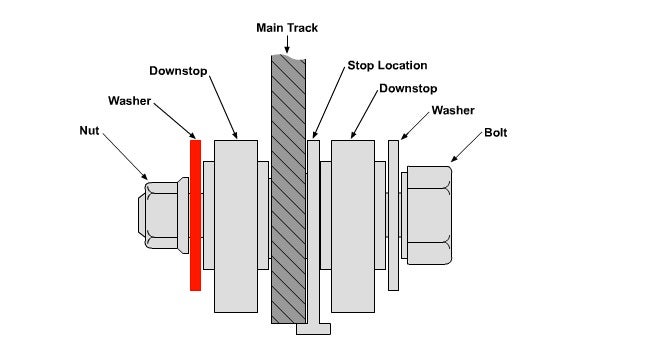

The first figure above shows the Main Track in dark grey, and the Downstop Assembly in red, at the fullest extension of the slat. Investigators believe that after routine maintenance to the No. 5 Slat Can, technicians failed to replace the washer behind the nut (second illustration). This washer prevents the nut from passing through the Main Track as the nut is smaller than the hole in the Main Track.

At some point after maintenance, the bolt passed through the Track assembly and fell into the Slat Can. When the Main Track was retracted, it forced the bolt through the Track Can, puncturing the Can and causing a fuel leak. While taxiing, cool engine fan exhaust and air flow kept the fuel from reaching the hot engine and hot brakes. Once stopped on the tarmac, and the engine shut down, the fuel started leaking to these hot areas. Ground workers spotted the leaking fuel and alerted the flight crew. Soon after, the fuel ignited.

ncasolowork2

> ttyymmnn

ncasolowork2

> ttyymmnn

10/31/2013 at 10:09 |

|

I am thinking I hate you for posting this. The next time i have spare parts I'm going to worry about fiery death.

Jayhawk Jake

> ttyymmnn

Jayhawk Jake

> ttyymmnn

10/31/2013 at 10:17 |

|

This is an example of overlooking a small detail, something engineers really need to not do.

The fact that the nut diameter was smaller than the downstop should have been a HUGE red flag early on, and something easy to fix. Use a bigger nut, a smaller downstop diamter, some safety wire on the bolt (I can't believe it didn't have that)

Fortunately this happened on the ground, but it easily could have happened in the air.

ttyymmnn

> Jayhawk Jake

ttyymmnn

> Jayhawk Jake

10/31/2013 at 10:21 |

|

It would be interesting to see what, if any, recommendations were made by the FAA pursuant to this investigation. It's impossible to think of everything, and unfortunately, oversights are often discovered after an incident. But really, who makes a nut smaller than the hole?? There must have been a reason, and I'd be interested to know what that reason was.

FJ80WaitinForaLSV8

> ttyymmnn

FJ80WaitinForaLSV8

> ttyymmnn

10/31/2013 at 10:21 |

|

pretty wild. Thanks for sharing.

Jayhawk Jake

> ttyymmnn

Jayhawk Jake

> ttyymmnn

10/31/2013 at 10:24 |

|

The FAA may have made a general recommendation to not do that, but it's not something that should happen anyways.

I'm not a wing or fuel guy, so I'm not 100% up to speed on current FARs for wing fuel tanks, but it seems a little odd to me that it's even acceptable to have the slat track go into the fuel tank like that. It's possible that it's a design that got grandfathered in, but I can't be sure without pulling out a FAR handbook.

ttyymmnn

> Jayhawk Jake

ttyymmnn

> Jayhawk Jake

10/31/2013 at 10:28 |

|

I'm sure some engineer along the way in the design process said, "Look how much more fuel we can put in if we have the Track Can extend into the fuel tank. And another one probably said, "We can save some weight by using smaller nuts," or, "We can use a smaller nut, make the Track Can thinner, and allow for more fuel." I would hope that the maintenance check list for these repairs includes making sure that the washer is in place. I bet it does now.

Jayhawk Jake

> ttyymmnn

Jayhawk Jake

> ttyymmnn

10/31/2013 at 10:51 |

|

I doubt it was like that.

They probably designed the wing first, with fuel tanks. Realized later on they needed more space than anticipated for the flap track, so the pocket was made.

The nut, beyond me. Probably didn't think about it. The washer was put in place to retain the nut from passing through the downstop. They didn't think about the washer not being in place.

The maintenance check list should have and probably did include the washer. It's part of that bolt stackup, there's no reason for it to not be there.

DoubleClutchingAutomatic

> ttyymmnn

DoubleClutchingAutomatic

> ttyymmnn

10/31/2013 at 11:17 |

|

Washer's aren't always important! (3:15 in vid)

smitdoshi

> Jayhawk Jake

smitdoshi

> Jayhawk Jake

10/31/2013 at 15:23 |

|

according to the video it says while the engine was running there is a cool layer of air which forms above the hot layer of air coming from the engine allowing the fuel to leak out and not cause a fire. It was upon engine shut down the fuel reached the Hot engine and the Brakes which ignited the fire. Not sure how this would have turned out in the air. i get the feeling the fire would not have occurred in mid air but would love for someone to provide input.

Jayhawk Jake

> smitdoshi

Jayhawk Jake

> smitdoshi

10/31/2013 at 15:32 |

|

There's many factors that would have led to it possibly causing a fire.

Fuel would have been leaking and atomizing, possibly reaching the exhaust of the engine, or nearing any surface that has reached ignition temperature.

Additionally, in doing maneuvers the fuel would slosh around, and possibly end up somewhere it's not supposed to. Maybe it reaches a bleed air duct and ignites. Or maybe it reaches an actuator, causes a short, and ignites.

We'll never know what could have happened, but the danger of the situation becomes much, much worse when you are in the air.

ttyymmnn

> FJ80WaitinForaLSV8

ttyymmnn

> FJ80WaitinForaLSV8

10/31/2013 at 15:40 |

|

My pleasure.